Any solar kit basically consists of three parts: Solar panel. charge regulator and a battery (usually the one already installed on your boat / caravan / …). The solar panel converts sunlight into electric energy with an almost constant voltage which is then transformed to the right charging curve by the charge regulator. Wiring such a system is very simple and can usually be done by the customer himself.

When selecting the single components a couple of things have to be put into consideration. Our team will be happy to assist free of charge.

Here you can find basic information concerning what needs to be put into consideration when selecting the parts:

Solar panels

Solar panels are the heart of the system, converting sunlight into electric energy. Depending on the surface you have available, the power needed and the budget you will have a variety of options. Always keep in mind: Even if the system is not big enough to make you completely self-sufficient it will still prolong the runtime of your battery and its lifetime due to keeping it charged when not in use. Even a small system will therefore result in a higher level of comfort onboard.

Power

The power needed mainly depends on the equipment that should be run off the solar system. This can be calculated as follows: The current each equipment needs (in ampere) is multiplied with the time it is used on a normal day (in hours). The resulting values of all your equipment are summed up and result in your total needs in ampere-hours (Ah).

For converting the ampere-hours into your daily energy usage in watt-hours (Wh), these are multiplied with the system voltage. The following values are used for common system voltages (these are also adding a little reserve capacity): 12V battery: 14,0V | 24V battery: 28,0V

Use this form to calculate the daily energy need of your equipment:

After having calculated our daily energy need (sum of the Wh values of all equipment onboard) we can now proceed to calculating the solar power needed to run this system.

All solar panels are marked with a “Wp” value, meaning watt-peak or the maximum power this solar panel can deliver (measured at 1000W / m² sunlight and a cell temperature of 25°C). As the sun is not shining with full power all day (clouds, sunlight angle, …) the actual power delivered will be below that value most of the time. The Wp-value can anyway be used to estimate the daily energy yield – in central Europe for a horizontally-mounted solar panel without direct shade it can simply be multiplied by 4, in areas with more sunlight this value can be a bit higher (we are regularly seeing factors of 6+ in the southern mediterranean). If the panel will regularly see shadow from equipment mounted nearby, reduce the factor a bit to be on the safe side.

Solar panels having the peak power (Wp) calculated like this will be able to deliver enough energy on an average day to fill up the battery for another full day of use. For a self-sufficient system it is recommended to install a system with more power to be able to store enough energy even on cloudy or rainy days.

Cell type

Solbian works with three different cells types, differing in efficiency, mechanical resistance and cost per Wp.

Higher efficiency means the cell can achieve a higher power on the same surface compared to lower efficiency cells.

SP series

SP series panels are using the most efficient cells currently available on the market: SunPower™ MAXEON BackContact with a cell efficiency of 24%. This high efficiency allows very high power on small surface areas, a substructure of massive copper strengthens the cell mechanically for very high mechanical resistance. BackContact technology makes these panels aesthetically pleasing as no bus-bars or conductors are visible: With black backsheet and hidden contact ribbons we can manufacturer completely black panels blending into any design concept.

Another key spec of these cells is the good low-light performance and their low temperature coefficient, meaning they loose less power in hot conditions than other solar cells. This gives our SP series a higher overall energy yield compared to other panels with the same nominal power.

SXX series

Same size, more power: the SXX series comes at the same size of standard 6 inches cell panels but generates more power, thanks to its Silicon-based heterojunction solar cells (HJT) that offer more than 23% of efficiency. When compared with panels of the same nominal power, the SXX prove to harvest more energy due to HJT cells being intrinsically bifacial, an important feature especially when panels are encapsulated in a transparent sandwich and installed where indirect light can reach the rear of the panel. To top it all, HJT cells perform better than others in hot climates thanks to very low temperature coefficients.

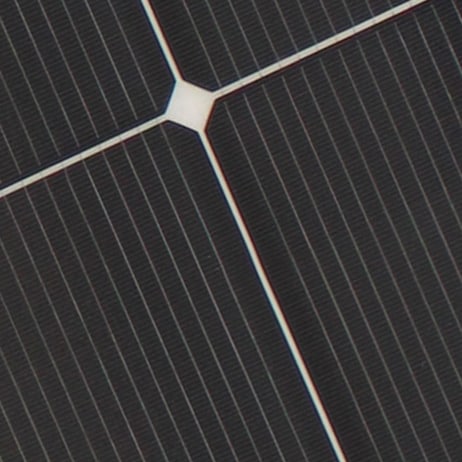

In the SXX series the monocrystalline solar cells are electrically connected using ultra-thin copper wires that form a very fine mesh on the cell surface, resulting in thousands of contact points. This alternative to the standard bus-bar method allows a higher module power and increases the energy yield. A technology optimally suited to flexible modules, due to its intrinsic insensitivity to micro-cracks, that are the most common cause of energy loss in solar modules.

SR series

Our SR series panels use monocrystalline cells with efficiency levels above 20%. These are embedded in a sandwich of two metallic grids – the upper one progressively gaining strength in direction of the current flow, the lower one reinforcing the cell mechanically. This patented technology not only gives a very good energy yield and shade tolerance but strengthens the cell and makes sure it continues to work even if the cell itself should break. This makes them perfect for installations with continuous movement and high mechanical forces like those applied on textile surfaces.

The bigger SR series cells (6” compared to the 5” SP cells) allow us to realize a different range of panel sizes, giving you even more flexibility in your system layout. Featuring a price tag roughly 25% below the SP series they are very interesting for applications where maximum power density is not needed but mechanical resistance is still a key factor.

SX series

The SX series uses the same monocrystalline cells as the SR series (efficiency >20%), however a different contacting technology is applied. The cells electrically connected using ultra-thin copper wires that form a very fine mesh on the cell surface, resulting in thousands of contact points. This alternative to the standard bus-bar method allows a higher module power and increases the energy yield. A technology optimally suited for flexible modules due to its intrinsic insensitivity to micro-cracks, the most common cause of energy loss in solar modules. Another advantage is a reduced sensitivity to shading, pushed to the extreme in the Guardian (G) models where additional bypass diodes are inserted thanks to an innovative cell layout.

As these cells are finalized in-house at Solbian we are able to offer them at a very competitive price – the SX series is perfectly suited for installations with medium mechanical stress and bigger surface areas, like caravans, architectural or industrial applications.

ALLinONE series

The ALLinONE series enhances all the technologies mentioned above with panel-integrated waterproof MPPT charge regulators. These panels can directly be connected to the battery with the high-efficiency step-up-MPPT regulator making sure the maximum possible amount of energy arrives at the battery. Step-up technology gives these panels exceptional low-light and shade performance.

Perfect for mobile systems and panels used to top up the battery when not onboard. Also strongly used in the industrial sector to keep the batteries of big machinery topped up when not in use.

Installation

The low weight, flexible laminate and wide range of options for customization makes SolbianFlex panels suitable for a great variety of installations. If you are not sure where and/or how to integrate your photovoltaic system our specialists will be happy to assist you free of charge.

Rigid surfaces

When bonded to a rigid surface, SolbianFlex solar panels are fully walkable and able to withstand high mechanical forces. For quick and reliable installation they can be delivered pre-equipped with a special acrylate adhesive layer, featuring the perfect physical properties for mechanical strength and thermal expansion. Installation only requires cleaning the surface and removing the protective film, an optical finish can be given by sealing the edge with UV-resistant sealant.

For perfect integration we recommend using our innovative rear-wire option, leading to an installation with invisible and perfectly waterproof wiring below the panels.

For wiring these panels we can of course offer a wide range of different solutions, from invisible rear wires to various junction boxes with waterproof connectors or open wires.

Textile structures

Due to their low weight (2,1kg / m²) our panels can be integrated in textile surfaces without additional strengthening. For installation we offer stainless steel eyelets, LOXX quick-connect, zippers or velcro solutions. While eyelets and LOXX are suitable for temporary installations we recommend using zippers or velcro for more permanent solutions as these close the sides and make the system more wind-proof.

If possible, the panels should be installed on homogenous surfaces without and internal sharp edges or protruding structures to avoid the cells being bent too much – if that is the case we have different solutions to stiffen the panels and avoid damage.

Mobile use

If the panels are to be used flexible and on different locations, stainless steel eyelets are the way to go – these can be used to fix the panels with cable ties, ropes and many other tools. Their weight and compact size makes the panels easy to handle, for storage they can as an example simply be put under a mattress.

Charge regulators

The charge regulator connects the solar panel and the battery. This device transforms the voltage of the solar panel in a charge curve for the battery to ensure maximum energy yield and longer battery lifetime.

MPPT or PWM?

The data-sheet tells us the nominal voltage (V_oc being the open-circuit voltage and V_mpp being the maximum power point voltage) and the maximum current of the panel. In reality these values will vary: Different lighting conditions will lead to different current output while changes in cell temperature can affect panel voltage slightly. Also, the overall conditions affect the voltage where the panel is able to deliver its maximum power.

PWM regulators can simplified be described as electrical switches, directly connecting and disconnecting the panel to/from the battery depending on its voltage. Panel voltage is being pulled down to the battery voltage while the current the panel can deliver stays constant – this means that if the panel could deliver a higher voltage this energy remains unused. The panel voltage needs to match the battery voltage for good results, limiting possible cell layouts.

MPPT regulators use highly efficient DC/DC converters to transform the panel voltage into a charging curve matching the battery type. Algorithms constantly check different panel voltages to make sure the solar panel is used at its maximum power point (the sweet spot where voltage and current result in maximum power). This not only allows a wide range of cell layouts (e.g. a 100V solar panel can charge a 12V battery) but maximizes energy yield in difficult lighting conditions, resulting in a significantly higher energy yield compared to PWM regulators even in standard conditions.

Special boost-type MPPT regulators are even able to use lower-voltage panels to charge higher-voltage batteries (e.g. a 10V panel can charge a 48V battery).

When selecting the charge regulators you should carefully match voltages and maximum currents, also take care to select regulators with high efficiency to maximize the amount of energy actually reaching your battery. Small charge regulators needing active ventilation are for example a bad sign as this means a lot of heat is generated during the voltage transformation process.

At Solbian we exclusively work with high-efficiency MPPT charge regulators of leading manufacturers (Victron Energy, GenaSun, Western Co., Mastervolt), which we are happy to offer together with our solar panels.

Our team will be happy to assist you in finding the perfect charge regulators for your project – we are of course able to source custom regulators for special system voltages and battery types.

Shade – splitting the system with separate regulators

A solar panel’s biggest enemy is shade. In worst-case situations, even a very small shade covering a single cell can lead to big energy losses. Panel-integrated bypass diodes and optimized string layouts (standard with SolbianFlex panels) can reduce this problem, maximizing energy yield even in difficult mounting areas. In properly-planned systems, shaded areas are simply bribed by their bypass diode to allow the rest of the panel to continue producing energy. As bridging a part of the panel results in a voltage drop, the charge regulator needs to be MPPT-type and properly selected to continue working.

Another way of minimizing shadow effects is to connect panels in parallel – this way shadow on one panel can not affect the others. For parallel connection, blocking diodes between the panels are needed to avoid the other panels heating up the shaded one.

The perfect solution for applications where shadows are to be expected on a regular basis (e.g. sailing yachts and rooftops with antennas close to the solar panels) we strongly recommend using a separate charge regulator for each panel. This way, each regulator can run its panel at the maximum power point without shadow on one panel affecting the other. The cost for multiple small regulators is similar to the cost of one big unit, the main downside is having to run more wires. This solution guarantees maximum energy yield.

Panel voltage and power

Photovoltaic panels consist of multiple solar cells, which are connected in series. Each of these cells contributes a certain amount of volts to the total voltage (between 0,5V and 0,65V, depending on the cell type). The total panel voltage depends on the number of cells.

This voltage is an important factor when selecting the charge regulator: Most regulators need a panel voltage which is higher than the battery voltage to work properly. As the panel voltage rises in low temperatures, calculate at least 10% margin for the maximum voltage allowed for your regulator of choice to be on the safe side.

Special step-up regulators are able to work with lower panel voltages.

The second main factor for your selection process is the maximum power the panel can deliver. Charge regulators work best with 80-100% load so don’t choose it too big. On the other side, a regulator too small to use the full power of the panel will not be able to give you the maximum charge in good lighting conditions.

Battery type

Recent years have shown a trend towards new battery technologies: While flooded, gel and AGM lead batteries are still widely used different lithium chemistries have appeared, often connected with rising system voltages due to e-mobility and higher power needs. Each of these battery types needs specific charge parameters to maximize safety and system lifetime.

Close cooperation with leading manufacturers of MPPT charge regulators allows us to deliver the perfect match for each battery type and system voltage – we can even deliver custom electronics for exotic battery chemistries and system voltages. Our team will be happy to assist in the selection process.

Conclusion

A photovoltaic kit consists of solar panel and charge regulator to charge a battery. It is important to match these properly to achieve a maximum energy yield and good system performance.

Even if you do not have enough surface available to become completely self-sufficient a small solar system will still improve your battery runtime significantly. The prolonged battery lifetime reduces the system cost and the massive gain of comfort – e.g. not having to start the engine in a silent anchorage to charge your batteries – will quickly reward you for your investment.

If you are not able to find a matching solar panel in our brochure we will be happy to manufacture a custom size for you without any extra cost. Highest quality standards and modern test methods are used to make sure you can rely on our systems.